Lyocell fiber is a green fiber produced by a new solvent process. The so-called green fiber not only requires environmental protection of raw materials, biodegradable waste, but also requires all production processes to be "green", that is, in line with the requirements of modern environmental protection, no pollution to the environment. The new solvent used in the production process of Lyocell fiber is organic solvent NMMO

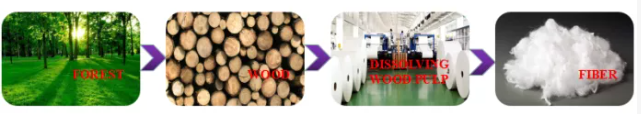

Lyocell fiber has a wide range of raw materials, such as trees, bamboo, straw and waste cotton staple that grow in large quantities in nature, which can be used to produce Lyocell fiber inexhaustible.

In these raw materials, there are abundant cellulose resources, which are natural polymer materials given to human beings by nature. By extracting these polymer cellulose through technical means, it becomes the raw pulp of Lyocell fiber, and then Lyocell fiber can be prepared by spinning processing.

In the textile field, Lyocell fiber has excellent wearability and can be blended with cotton, hemp, silk, wool and synthetic fiber at any proportion. Pure Lyocell fabric and blended fabric of different styles can be woven through different textile and knitting processes. For high-grade jeans, women's underwear, fashion and men's high-grade shirts, t-shirts and other casual wear.

In addition, Lyocell fiber products in the wet state, under the action of external mechanical friction, will produce obvious fibrillation phenomenon, which is reflected in the fiber longitudinal separation of smaller fibrillation, hair on the surface of the yarn. The properties of Lyocell fiber fibrilation can lead to peach skin style products from the finished fabric style.

In the field of home textiles, Lyocell fiber has good skin affinity and mechanical properties, and is widely used in bedding, bathroom products, home furnishings and so on.

In the field of industrial textiles, Lyocell fiber has a high strength, close to polyester, much higher than cotton, its wet strength is almost 85% of the dry strength, which is incomparable to other cellulose fibers. Lyocell fiber can be made into nonwovens with various properties by needling, spunking, wet laying, dry laying and hot bonding, etc. At present, it has been widely used in nonwovens, industrial press cloth, industrial silk and special paper.

Tags :