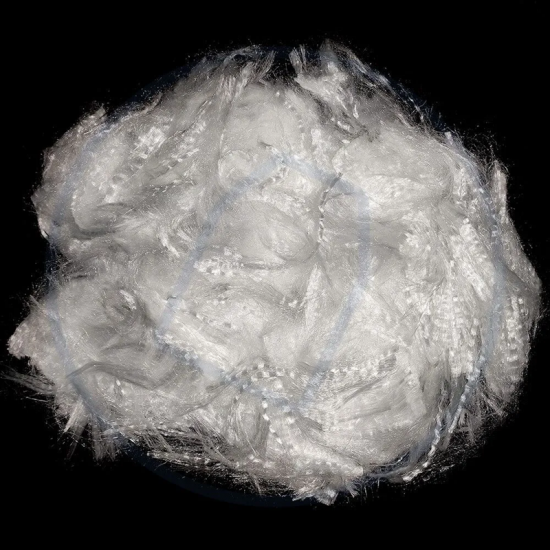

Thermochromic yarn is a kind of yarn that changes color repeatedly with rise or fall of temperature.Commonly used color change temperature is 31 degrees Celsius,commonly known as touch color change,hand color change.At present,there are pppe thermochromic yarn.

IPv6 network supported

IPv6 network supported