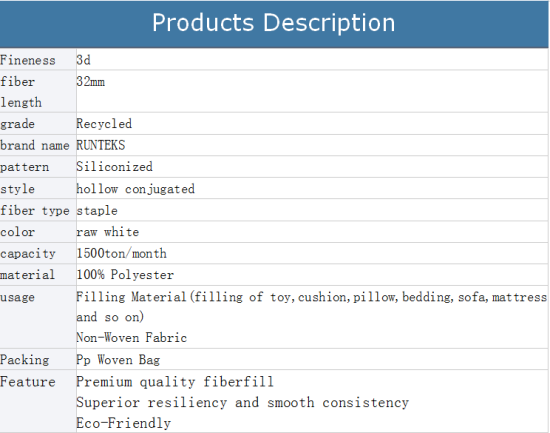

Filling Material

*Filling toys

*Filling Quilts

*Filling down coats

*Filling cushions and pillows

*Filling sofas

Non-Woven Fabric

*Producing non-woven

*Automotive Interiors

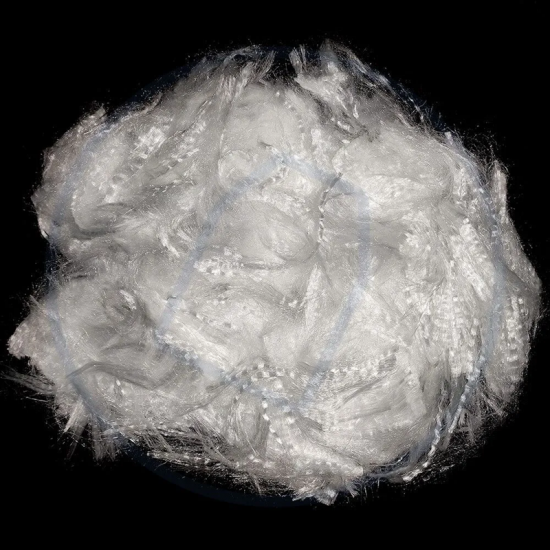

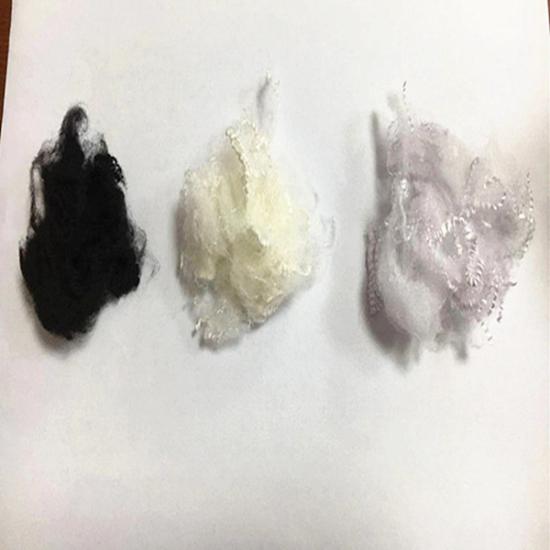

Chemical fiber is commonly known as "short fiber" and "short silk". Chemical fiber is formed and then cut into a certain length to obtain the product. According to the difference of thickness and product length, it can be divided into cotton staple fiber (commonly known as "artificial cotton"), wool staple fiber (commonly known as "artificial wool") and medium-long staple fiber (short for "medium-long fiber"). It can be spun on cotton, wool and other spinning machines or blended with cotton, wool and other fiber.

IPv6 network supported

IPv6 network supported