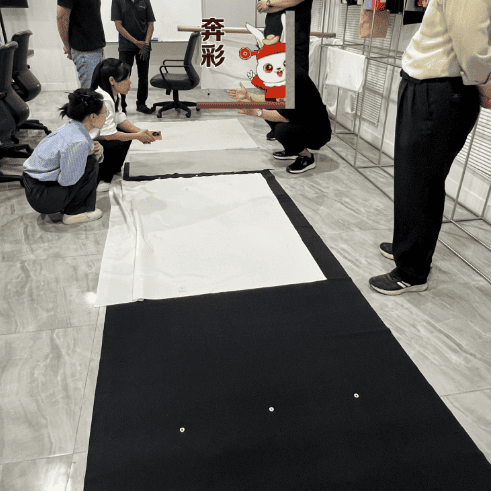

New generation of polyester that low temperature dyeing interweaving

Nov 01, 2024

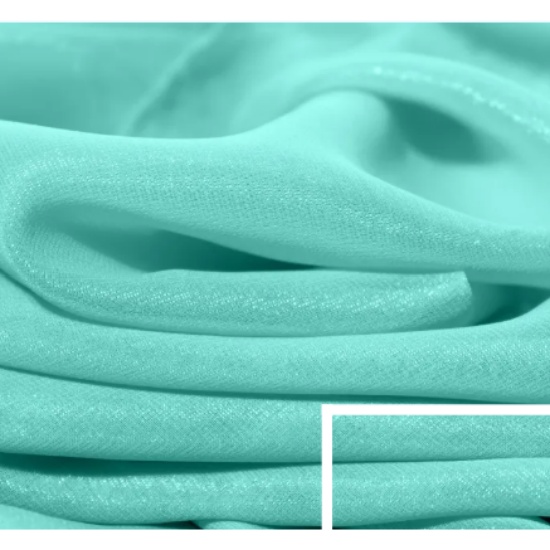

This new generation of polyester that randomly embeds hydrophilic groups and flexible segments into existing polymers, with the goal of being hydrophilic, easy to dye, concentrated, anti-static, and anti pilling. Hydrophilic, comfortable, moisture absorbing, and sweat wicking Naturally hydrophilic, it has better moisture regain and retention rate than conventional polyester. Combined with the fabric structure, it has the characteristics of rapid diffusion and evaporation when wet, providing a good cooling experience. Low static electricity, weak pilling, no itching Compared to ordinary polyester, polyester has lower electrostatic resistance and better anti pilling performance, reducing the itching sensation when worn. Low modulus, soft to the touch Compared to polyester of the same specification, the modulus of polyester can be reduced by 10% to 20%. The fabric woven from it has a soft touch, excellent cotton feel, and comfortable wearing. Low dyeing temperature and low setting temperature The dye uptake rate of atmospheric pressure boiling dyeing is 2-3% higher than that of ordinary polyester under high temperature and pressure, with excellent and stable color fastness. The heat setting temperature of the fabric is 15-20 ℃ lower than that of ordinary polyester, which can effectively improve the hand feel and softness.

View More